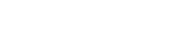

Failure Analysis

We thoroughly analyze products with defects found by customers. We identify the cause, address the problem, and prevent recurrence of the defect. We also conduct fault analysis and improvement for products with defects found in evaluation during development or in process faults at subcontractors.

Fault Analysis Equipment

| Purpose | Equipment |

|---|---|

| Failure point identification | ELITE (Enhanced Lock-In Thermal Emission) |

| EMS (Emission Microscope) | |

| OBIRCH (Optical Beam Induced Resistance Change) | |

| OBIC (Optical Beam Induced Current) | |

| TDR (Time Domain Reflectometry) | |

| EBAC (Electron Beam Absorbed Current) | |

| Manual prober | |

|

Grinding/ etching |

Plasma dry etcher |

| Grinding machine | |

| Draft (acid, HF, organic) | |

| Precision grinding system (CMP) | |

| Observation | SEM (Scanning Electron Microscope) + element analysis machine |

| FIB (Focused Ion Beam machine) | |

| X-ray observation equipment (3D-CT) | |

| SAT (Scanning Acoustic Tomography) | |

| Optical microscope (Stereoscopic, Gold sensible, IR) | |

| Others | LSI Tester + Thermo Stream |

| Semiconductor parameter analyzer | |

| Laser opener | |

| Plastic mold opener |

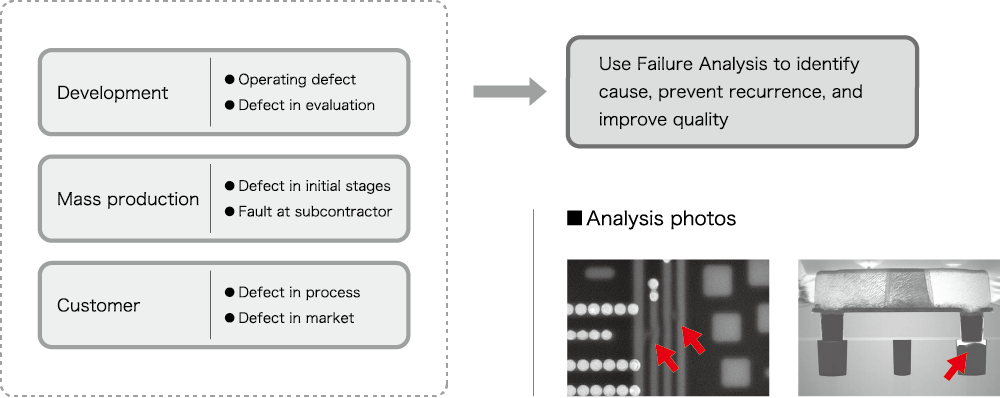

●Example of Failure Analysis Equipment